From Principle to Creation: Unleashing Creative Thinking With DTF Printing on Various Fabrics

In today's dynamic realm of textile style, the use of Direct to Movie (DTF) printing innovation has actually revolutionized the procedure of transferring elaborate layouts onto various textiles. The combination of innovation and creativity through DTF printing opens doors to a realm where creativity understands no bounds.

Checking Out the Benefits of DTF Printing

Why is DTF printing increasingly favored over various other techniques for its flexibility and sturdiness in the fabrics market? Direct-to-film (DTF) printing has been acquiring traction in the textiles sector due to its many benefits that satisfy the progressing needs of the market. One vital benefit of DTF printing is its versatility in terms of the materials it can be related to. Unlike some standard methods that are limited to details textile kinds, DTF printing can be made use of on a wide variety of materials, including cotton, polyester, blends, and also natural leather. This versatility permits higher imagination and technology in fabric layout.

Moreover, DTF printing uses outstanding resilience, making it perfect for creating resilient designs on fabrics - DTF Printing. The prints created via DTF are known for their dynamic colors and resistance to fading, fracturing, or peeling - guaranteeing that the end product maintains its top quality also after multiple cleans or expanded usage. This durability makes DTF publishing an economical remedy for manufacturers seeking to produce high-grade, lasting designs on fabrics

Designing With DTF: Advice

Creating properly with DTF printing entails grasping the complexities of digital design software program and understanding exactly how to optimize styles for the ideal results on numerous textiles. When producing styles for DTF printing, it is essential to consider the fabric shade, structure, and type to guarantee that the end product fulfills expectations. Below are some techniques and pointers to enhance your DTF style procedure:

Resolution is Key: Begin with high-resolution images to keep clarity and intensity in your designs. Low-resolution photos can cause a pixelated last item.

Shade Matching: Pay focus to color accuracy when developing for DTF printing. Usage color administration devices to make certain that the shades in your design equate precisely onto the material.

Vector Graphics: Make use of vector graphics anywhere possible to keep the quality of your layouts when scaling them to various dimensions. (DTF Printing)

Examination Prints: Constantly perform test prints on example textiles to examine the colors, resolution, and total design high quality prior to major manufacturing.

Choosing the Right Fabrics for DTF

When taking into consideration the optimal fabrics for DTF printing, the option of product plays a vital duty in achieving the wanted high quality and resilience of the last published designs. Selecting the appropriate textile is crucial for ensuring that the shades adhere well, the design remains vivid and sharp, and the total look fulfills assumptions. Fabrics with a high polyester web content are normally chosen for DTF printing due to their capability to hold the ink well and generate vivid prints. Polyester blends can additionally function effectively, using an equilibrium between durability and print top quality. Furthermore, materials with a smooth structure have a tendency to produce better outcomes as they supply a consistent surface area for printing, permitting specific detailing and color precision. It is necessary to take into consideration the desired usage of the published fabric when choosing the material, as different materials supply varying levels of stretch, breathability, and washability. By carefully selecting the appropriate material for DTF printing, creators can improve the durability and aesthetic influence of their styles.

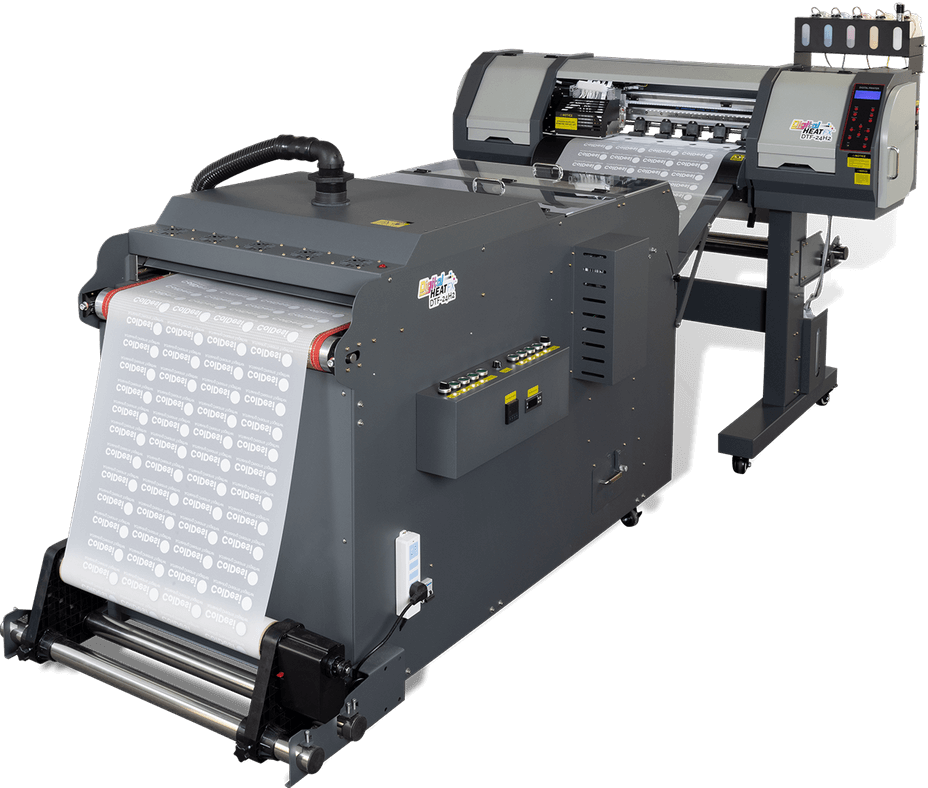

Step-by-Step DTF Printing Refine

After curing, the printed design is after that moved onto the material using a heat press. The transfer procedure needs careful placement to make sure that the style is applied precisely. When the transfer is full, the textile is permitted to cool prior to the transfer movie is removed, leaving the vibrant and durable layout on the fabric. Ultimately, the fabric may undertake post-processing treatments to enhance the layout's durability and vibrancy, causing a high-grade final product on-line or screen.

Showcasing DTF Masterpieces

Have you ever wondered at the detailed details and vivid colors of DTF work of arts showcased on various textiles? DTF printing has reinvented the means designs are transferred onto textiles, permitting for unrivaled accuracy and go to website richness in colors. When these DTF work of arts are placed on screen, they captivate audiences with their striking visuals and thorough workmanship.

Among one of the most exciting facets of showcasing DTF work of arts is the versatility it offers. Whether it's a appealing and strong design on a t-shirt, a comprehensive pattern on a pillowcase, or a custom print on a canvas bag, DTF printing enables endless possibilities. This flexibility enables designers and musicians to release their creativity and bring their visions to life on a large range of fabrics.

In addition, the longevity of DTF prints guarantees that these explanation work of arts can withstand the test of time without shedding their vibrancy. Whether shown in galleries, worn as stylish garments, or used as attractive accents in homes, DTF masterpieces continue to excite visitors with their outstanding top quality and visual allure.

Final Thought

Finally, DTF printing offers a versatile and innovative technique for letting loose imagination on different materials. By discovering the benefits of DTF printing, designing with specific suggestions and tricks, choosing proper textiles, and complying with a step-by-step printing procedure, artists can display their masterpieces effortlessly. This procedure enables the smooth shift from idea to development, supplying countless opportunities for imaginative expression.

In today's vibrant realm of textile style, the application of Direct to Film (DTF) printing innovation has actually reinvented the process of transferring detailed designs onto various fabrics.Designing successfully with DTF printing involves mastering the details of digital design software program and recognizing exactly how to enhance layouts for the ideal outcomes on numerous fabrics.When thinking about the optimal textiles for DTF printing, the selection of product plays a crucial duty in attaining the wanted quality and resilience of the final published designs. The following step is printing the design onto a special DTF transfer learn the facts here now movie using a DTF printer with the suitable ink. By checking out the benefits of DTF printing, making with certain ideas and techniques, selecting ideal materials, and adhering to a detailed printing process, artists can showcase their masterpieces with ease.